Thermal deformation is one of the reasons that affects machining accuracy. Drillstar Machines are affected by changes in workshop environment temperature, electric motor heating, mechanical motion friction heating, cutting heat, and cooling media, resulting in uneven temperature rise in various par

Read More

The processing characteristics of deep hole drills: 1. The Drillstar tool holder is limited by the aperture, with a small diameter and a large length, resulting in poor rigidity and low strength. It is prone to vibration, ripples, and taper during cutting, which affects the straightness and surfac

Read More

Hard alloy is an alloy made by powder metallurgy with one or several refractory carbides (tungsten carbide, titanium carbide, etc.) as the main component, and metal powders (cobalt, nickel, etc.) added as adhesives. It is mainly used for manufacturing high-speed cutting tools and cutting tools for h

Read More

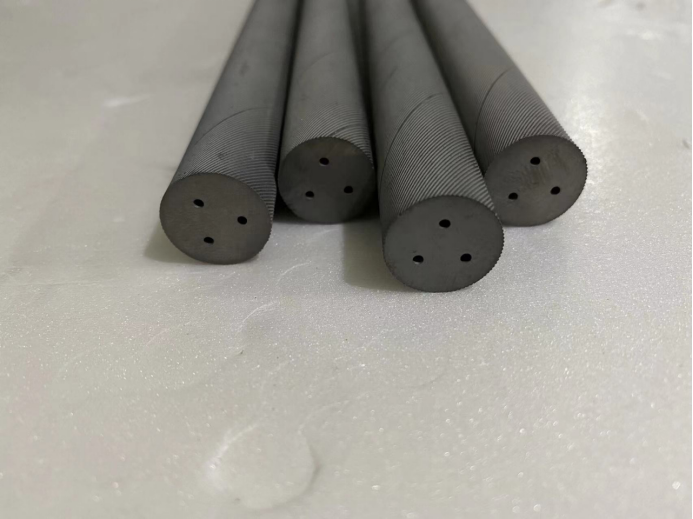

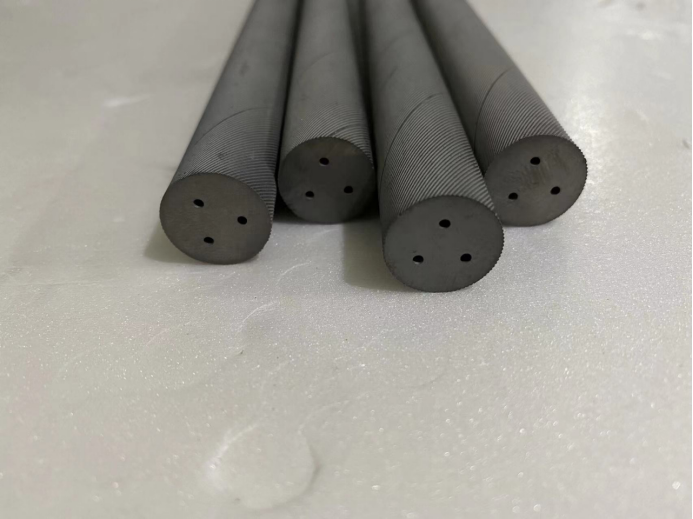

Tungsten carbide round rod is a composite material produced by powder metallurgy, consisting of refractory metal compounds (hard phases) and bonding metals (bonding phases). Tungsten carbide is a different local term.

Read More

In order to achieve better quality cutting and maximize tool life, we need to inspect the blades after machining, summarize the causes of different forms of blade wear, and find solutions, which are the foundation of successful milling.Rear blade wear 1Rapid wear leading to poor surface quality or e

Read More